Lasers & Catheter Technologies

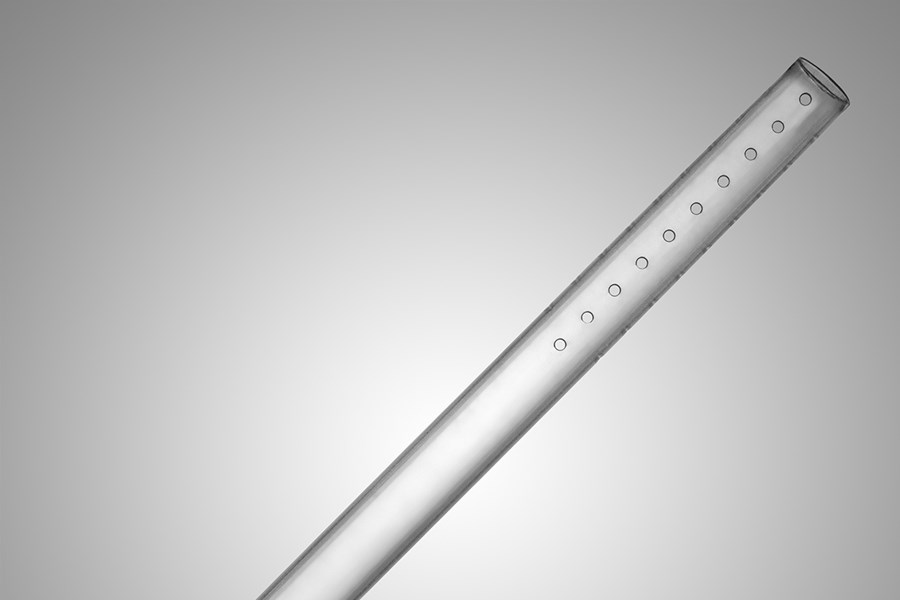

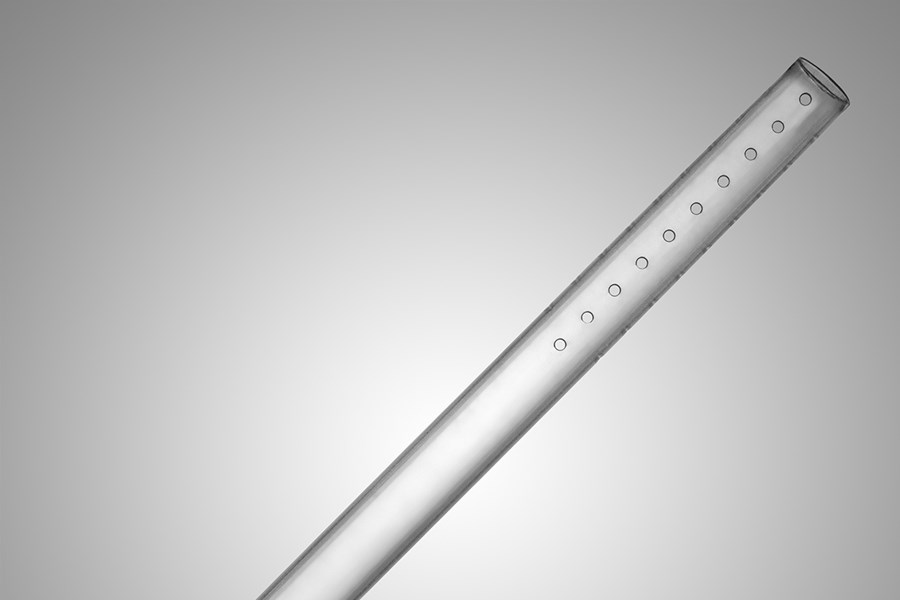

As medical catheters become smaller and more complex, lasers are increasingly the preferred technology for creating complex, micron-sized features in a range of materials.

Lasers & Catheter Technologies

As medical catheters become smaller and more complex, lasers are increasingly the preferred technology for creating complex, micron-sized features in a range of materials.

Lasers, which offer high speeds, incredible precision, and the ability to process without thermally altering the surrounding material, are ideal for removing material through ablation or drilling a variety of micron-sized features in catheter tubing and other materials. As medical catheters become smaller and more complex, lasers are often the only manufacturing technology capable of delivering the necessary accuracy.

Common laser processing applications for medical catheters include:

Catheters are increasingly complex in their designs. Medical device companies seek to add more functionality in less space—for example, multi-durometer or multi-material designs, multi-lumen extrusions with complex profiles and mechanical properties, and inner and outer diameters that continue to get smaller, with thinner walls. As catheter complexity increases, so does the range of medical applications for laser processing. These applications include:

The type of laser selected and the process (laser cut, drill, ablation) depends largely on the features being created and the catheter material selected. For example:

Laser processing applications will continue to advance as medical device manufacturers incorporate more complex designs, materials, and added functionality. Often the best solutions result from collaboration between customer and supplier engineering teams to create proprietary laser systems that push the technical limits of laser micromachining and make extraordinary designs a reality.